PCB Assembly Manufacturer

Mustar Is A Turnkey PCBA Manufacturer. We Focuses on PCB Making, Component Sourcing, PCB Assembly Since 1998.

We have Rich Experience to Help Brand Owners Fulfill Complete Products.

Certified Quality

ISO 9001, IATF 16949, and ISO 13485 certified to ensure high reliability and safety.

One-Stop PCBA Service

Comprehensive solutions from PCB manufacturing to assembly and testing.

Advanced Manufacturing

Precision production with expertise in multilayer, flex, and rigid-flex PCBs.

Flexible Customization

Fast prototyping, small-batch production, and 24/7 engineering support.

MUSTAR

OUR SERVICE

We provide high-quality PCB and PCBA solutions with end-to-end services — from design support, manufacturing, and assembly to quality assurance and fast global delivery, helping your innovations come to life efficiently and reliably.

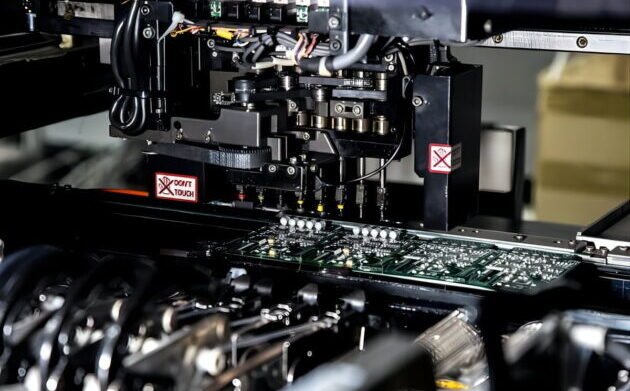

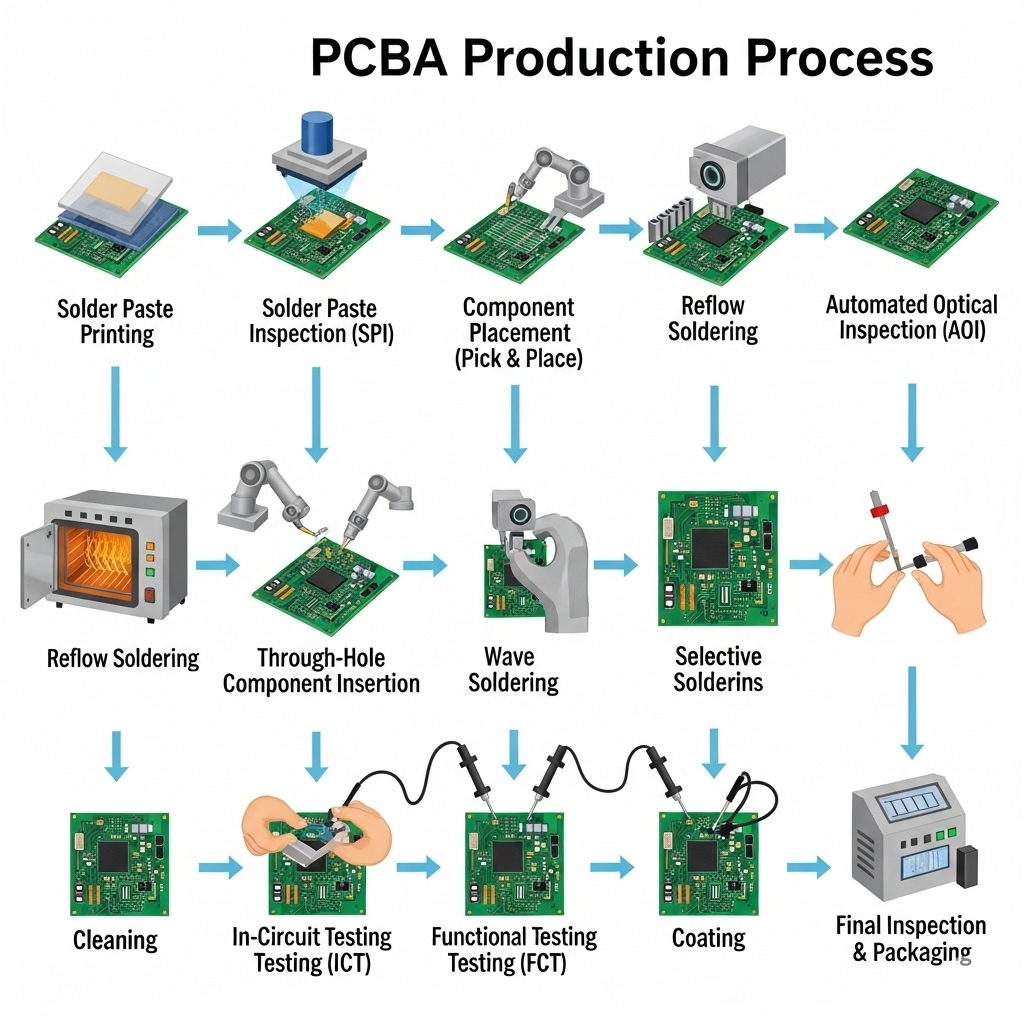

PCB ASSEMBLY(PCBA) SERVICES

PCBA Assembly Technology:01005, BGA, QFN Complete Quality Control System and Standardized Operation Process Our factory has 16 SMT lines, 1 X-ray machine, 32pcs AOI equipments, 2pcs first sampe testing equipments, factory area is 12000㎡, we have total 500 employees. We mainly specialized in product customization on Medical/ Health/ Automotive/ New Energy/ Industrial Control field. Electronic Components Sourcing

Electronic Components Sourcing BOM Service

500K IC DATA ONLINE QUERY 50 Pro Purchasing Agent with 10 years' EXP Mustar's global Procurement Engineer Team can provide you with continuous quality alternative components Our price is 10% lower than other suppliers basic same quality. Quality First Approach(We have Completed QC System.) On-Going Support On-Time Delivery(24 hours delivery)

FPC & PCB MANUFACTURING

We are able to customize PCB 1-64 layers. Base Material:CIM-1, CIM-3, FR-4, aluminum substrate, ROGERS , High-frequency Circuit Board. Complex PCB:Rigid flex,Teflon,HDl,Thick copper, impedance controller PCB production fabrication. Design for Manufacturing(DFM) Checking; 8 hours Quick turn PCB manufacturing, No moq; ISO14001,ISO9001,ISO13485,IATF16949,RoHS, UL, IPC 600G/ 6012B classll standard;

PCBA Core Application

PCBA In Medical Field

Certified, high-precision PCBA solutions meeting medical-grade standards for safe and reliable healthcare devices.

Mustar

PCBA customized service

PCBA customized service by Mustar delivers end-to-end solutions from PCB fabrication to full assembly, tailored to your product requirements with speed and precision.

One-Stop Turnkey Solution

From PCB production to final assembly and testing—everything under one roof for seamless integration.

Fast Prototyping & Delivery

Rapid sample preparation and on-time delivery help you accelerate go-to-market timelines.

Industry-Certified Quality

Complies with ISO 9001, ISO 13485, IATF 16949, and RoHS standards, ensuring high reliability for demanding sectors.

Flexible Customization

Support for low to high-volume orders with tailored component sourcing and layout optimization.

Factory Strength

Cooperate with famous component manufacturer to ensure 100% original and new, quality and competitive cost.Factory area is 12000 ㎡ , 20 SMT Lines, 6 DIP lines with full-automatic machine to delivery on time,also have no MOQ, prototype order is also welcome.

Custom Projects Completed

ABOUT US

MU STAR, TOP 1 PCBA MANUFACTURER IN SHENZHEN

Mustar was founded by Karma in 1998, have done business with over 98 countries, serve for Germany Telecom since 2016.

We focus on providing customers with one-stop printed circuit board assembly(PCBA) services, including PCB manufacturing, Electronic components sourcing, SMT, DIP, Enclosure assembly, Fast sample preparation, Programming test, OEM, ODM etc. We taking charge over 5000 electronic projects and mainly specialized in product customization on Medical/ Health/ Automotive/ New Energy/ Industrial Control field etc.

Our Factory

TOP 10 PCBA Manufacturer in China

Our Factory

At present, our factory is 12,000 square meters with more than 600 employees (Including more than 100 professional International sales, more than 50 Components sourcing engineers with over 5 years’ experience, more than 50 Quality control personnel).

There are 20 SMT lines (4 SMT lines are specially used for the production of Medical and Automotive products), 2 Fast sample preparation lines, 6 DIP lines, 3 Post welding lines, 3 Assembly lines and 3 Test lines).

HOW to order?

Ordering Process

Submit Your Requirements

Upload your Gerber files, BOM list, assembly drawings, and any special process instructions.

Project Evaluation & Quotation

Our engineering team will review your files and provide a detailed quotation with lead time.

Order Confirmation & Payment

Confirm the quotation and production details, sign the order, and complete the payment.

Production & Delivery

We proceed with PCB manufacturing, component sourcing, and assembly, followed by quality testing and on-time shipment.

PCBA Projects

Our customized solutions help you accelerate innovation across automotive, medical, industrial, and energy industries.

PCBA Solutions for Medical Imaging Equipment

Delivering high-reliability PCBA solutions tailored for advanced medical imaging systems, ensuring precision, stability, and compliance with industry standards.

Reliable PCBA Solutions for Medical Devices

Enhance patient care with our high-performance PCBA solutions — built for accuracy, reliability, and seamless integration in critical medical monitoring systems.

PCBA Solutions for Ventilators

Empowering ventilators with high-reliability PCBA technology to ensure precise airflow control, patient safety, and continuous performance in critical care environments.

PCBA Solutions for Solar Inverters

Delivering high-efficiency PCBA solutions for solar inverters, ensuring stable power conversion, enhanced durability, and optimal performance in renewable energy systems.

PCBA Solutions for EV Chargers

Powering EV chargers with reliable PCBA technology, delivering efficient energy transfer, robust safety features, and long-term operational stability for the e-mobility future.

PCBA Solutions for Automotive Battery Management Systems

Delivering precision PCBA technology for automotive BMS, ensuring accurate battery monitoring, optimal energy management, and superior safety for electric and hybrid vehicles.

Our Customers

Core Cooperative Customers

Walmart

Partnered in OEM consumer electronics PCBA production with rapid lead times and cost-effective solutions.

Danfoss

Provided high-reliability PCBA for industrial control and HVAC systems, meeting strict European quality standards.

3B medical

Supplied precision PCBA for respiratory and sleep therapy devices, ensuring ISO 13485 medical compliance.

Q-loud

Delivered customized IoT control boards with secure communication protocols, supporting their smart home initiatives.

What People Think About Us

We are proud to earn the trust of our clients worldwide. Their feedback drives us to continuously deliver high-quality PCBA solutions, fast turnaround, and exceptional service for every project.

Mustar has been an outstanding partner for our PCBA needs. Their fast prototyping and consistent quality helped us speed up our product launches without any compromise on reliability.

We appreciate Mustar's flexibility and technical expertise. From small batches to large production runs, they always deliver high-quality PCBA assemblies on time and within budget.

Thanks to Mustar’s professional team and strict quality control, our medical devices have met international certification standards effortlessly. Highly recommended for any precision PCBA projects.

Frequently Asked Questions

Yes,we support 3-7 days fast proofing.

Your files are held with utmost security. We protect the intellectual property of our customers throughout the entire process. All documents from customers are never shared with third parties (or are not shared with any third parties). An NDA can be signed.

There is no MOQ. We are able to handle small as well as large volume production with flexibility. We have two fast proofing production lines.

We can offer OEM service including PCBA making, PCB assembly, components sourcing. Additionally, we can also provide programming, testing, cables, enclosure assembly service.

ln order to guarantee PCB product quality,usually tested by flying probe; electrical fixture; automated optical inspection (AOI); X-ray inspection for BGA parts; first article inspection (FAl), and so on.

Gerber or Eagle, BOM listing, PNP and Components Position.